Electric car kit homologated in Spain ? Yes, for the Mini.

In recent years, electric cars have become more and more common, and the question of which electric car to buy is becoming increasingly common. With

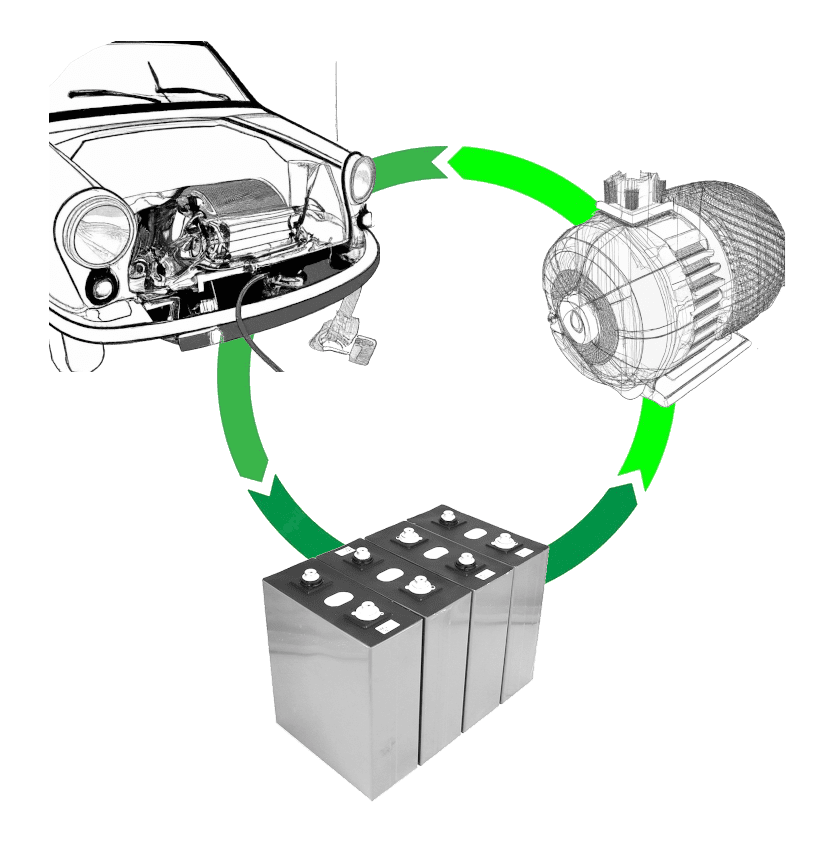

We enter into an engineering process where the most efficient engine, together with the most appropriate battery pack for the vehicle is designed and tested until the best prototype is achieved.

We certify the batteries and the complete it to facilitate all the bureaucracy and documentation to the final customer. Homologated, installed and ready.

A kit so easy and quick to install that it is just another mechanic's operation in any mechanic's workshop.

With the kit properly installed, you can access the new technical data sheet at the ITV and apply for the Zero Emissions label.

Fleet electrification is an increasingly popular solution to reduce greenhouse gas emissions in cities and improve energy efficiency. This solution is being implemented all over the world, from large companies to small local businesses. The conversion of vehicle fleets provides transport and last mile delivery companies with an efficient way to reduce their greenhouse gas emissions. This achieves a return on investment several years earlier than the purchase of new electric vehicles.

Your car is more than a possession, it is an expansion of you, it allows you freedom of movement. At Elektrun Cars our main concern is the environment, but we are also aware of the personal economy and the needs we have on a daily basis. We want to make it easy for you to finally have an electric car, whether you want to make it your personal project because you are a handyman or if you want us to convert it for you and return it to you ready to enjoy it in your daily life.

Converting your car to electric has several advantages. Firstly, electric cars are more efficient than traditional petrol vehicles. Electric cars do not need oil changes or regular tune-ups, and they produce no emissions. This makes them much better for the environment. In addition, electric cars are generally cheaper to run than petrol vehicles, as they require less maintenance and no petrol has to be purchased.

In recent years, electric cars have become more and more common, and the question of which electric car to buy is becoming increasingly common. With

It would be misleading to say that this birth has come easy, but we hope that it will come with a loaf of bread under its arm for the planet and above all for the planet.

After the Covid19 pandemic hiatus, courses can finally be organised with sufficient caution to be safe. We need as many as possible

Many of the concerns of our visitors and fans of the conversion of vehicles to electric vehicles are the homologations. The first thing to know is

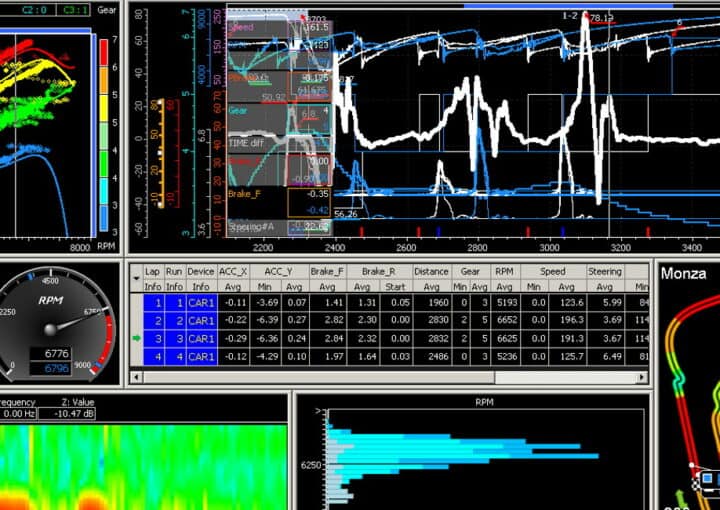

The Elektrun project, we went to the speed circuit of Cartagena with the prototype (The Electric Twingo), where we were able to use the track for quite a while.

You may have heard about us in:

There are all kinds of situations, from one week to 2 years. If you have all the parts, the chassis and the engine adapter plate, it can be ready in a few days working 8 hours on the assembly. On the other hand, choosing components, testing, designing some parts and using only weekends, can take one or more years.

It really takes a bit of courage, time and some basic knowledge of electricity and mechanics. As you are dealing with high voltages, a minimum of basic electrical and safety knowledge is a requirement. If you don't have it, it is a good idea to start reading and doing some research on the subject.

Any type is viable. But the easiest way to start is with a car that is small and light. A Renault Twingo, Volkswagen Polo, Mini, Ford Ka, etc.

You have to bear in mind that what you are going to recycle from your broken car is the chassis, the interior, the brakes and in some cases the gearbox. In other words, if what you have broken is the engine or any of its components, then it is perfect.

The first thing is to have a donor car, which is the one you are going to convert. Then there are 4 basic components which are an electric motor, a controller, a plate to adapt the motor to the vehicle's gearbox and a battery block. Then you need connectors, cables, fuses, contactors, a throttle, etc...

Using second hand reusable components, such as forklift motors and controllers, second hand boat batteries, etc. It can cost €2000 or €3000, whereas using new components can cost between €10,000 and €15,000. It also depends on how powerful the engine is, the mileage range of the battery pack, etc.

Well, here more than an answer could be written in a book. In fact, batteries are the most delicate and important component in terms of price, range, degradation, etc. in an electric car. As an example, with 1000€ you would have an AGM gel battery pack for about 50 kms, while with 4000€ you would have a lithium battery pack that could last for 200Kms.

Yes, gel or AGM batteries weigh a lot but are cheaper, while lithium batteries weigh half as much but are 4 times more expensive.

There are cars with basic motors that can reach 60 or 70 km/h, up to 150 km/h, passing through the typical 90 or 100km/h. A car of about 700kg, with a 15 kW electric motor, can reach 90 km/h perfectly.

This is the million-dollar question. The more batteries, the more kilometres you can do. For the example above, a 100 Ah battery pack would be enough for about 60 kms. On the other hand, in Slovenia they converted a Mazda 5 with a range of 700kms. And nowadays a range of 200kms is typical.

Yes, you would add 1 to 2 km more range. But it is not worth it.

This is a technology that is changing. There are already some small generators that produce enough current to power small motors. But weren't we trying to make an electric 100% car?

Yes, this is one of the great advantages of converting a car to electric, and that is that the transmission and other components are still used.

A small 12V vacuum pump, which consumes very little electricity, has to be fitted, and braking is the same or better than with the original braking system.

A second hand DC motor can be used, it is cheaper but less efficient. The ideal nowadays is to use induction AC motors, they are the perfect balance between price and efficiency. A 15 to 20 kW is perfect for a small city car.

In places with low temperatures, the batteries must be thermally insulated and a heating system must be installed for them. Lithium batteries are more delicate and for maximum efficiency they need a temperature of between 25º. They should not be charged at temperatures below 5°C.

Adding {{itemName}} to cart

Added {{itemName}} to cart