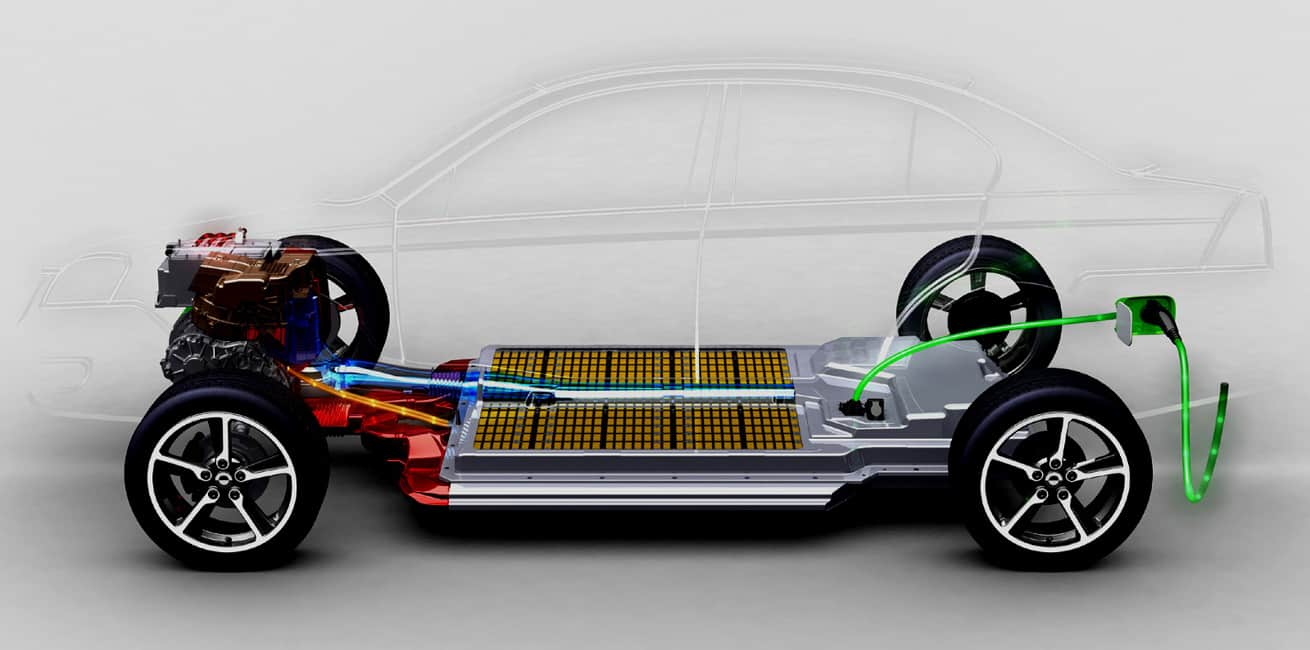

The battery world is in a constant state of flux at this time, with the electric car starting to take off, new electrical energy storage, supercapacitors and the new character, graphene.

Lead acid, AGM or gel batteries are now a thing of the past. We are now in the present with Li-ion and going into the future with Li-air.

The need for longer trips, faster charging times and better performance are already mandatory in electric vehicles, and more and more, these needs are an important issue in electric vehicles.

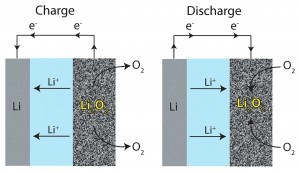

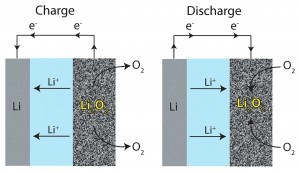

The way a li-air cell works is that they use a cheap carbon cathode (rather than cobalt), and an oxygen molecule pivots around the cathode, hence the name. But this is still theoretical because of the major challenges to overcome, such as the anode in these batteries is pure lithium metal, which provides a lot of energy but ignites in the presence of water or other pollutants.

Such was the challenge, that both IBM and JCESR (Centre for Energy Storage Research) have taken a step back from Li-air development, and IBM has now shifted in favour of lithium-sodium technology.

The way a li-air cell works is that they use a cheap carbon cathode (rather than cobalt), and an oxygen molecule pivots around the cathode, hence the name. But this is still theoretical because of the major challenges to overcome, such as the anode in these batteries is pure lithium metal, which provides a lot of energy but ignites in the presence of water or other pollutants.

Such was the challenge, that both IBM and JCESR (Centre for Energy Storage Research) have taken a step back from Li-air development, and IBM has now shifted in favour of lithium-sodium technology.

But with all these changes, new developments continue, and in metal chemistry there are still new developments, in particular in aluminium-air batteries. One Israeli company, Phinergy, claims to have solved corrosion and recharging problems with a silver-based catalyst. They claim to have built a prototype electric vehicle with a range of 1600kms using aluminium-air batteries. However, these batteries cannot be recharged electrically and have to be filled with water.

But with all these changes, new developments continue, and in metal chemistry there are still new developments, in particular in aluminium-air batteries. One Israeli company, Phinergy, claims to have solved corrosion and recharging problems with a silver-based catalyst. They claim to have built a prototype electric vehicle with a range of 1600kms using aluminium-air batteries. However, these batteries cannot be recharged electrically and have to be filled with water.

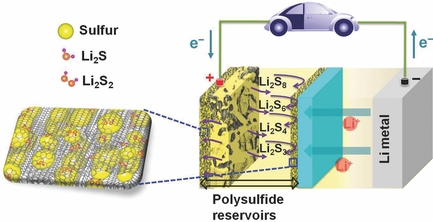

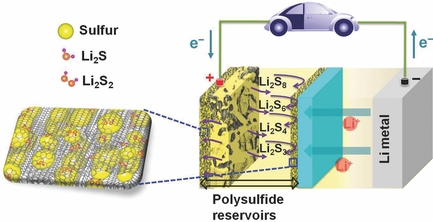

Many studies and laboratories, from Imperial College to the German company Bosch, are now turning to the development of Li-S (sulphur), claiming that it will be the 4th generation of batteries, with expectations of up to 400kms of range in the next decade. Scientists at Lawrence Berkeley Laboratory (California) have introduced graphene oxide into Li-S cells with no deterioration over 1500 charge cycles.

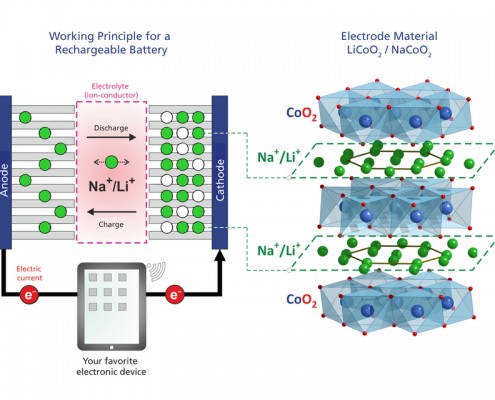

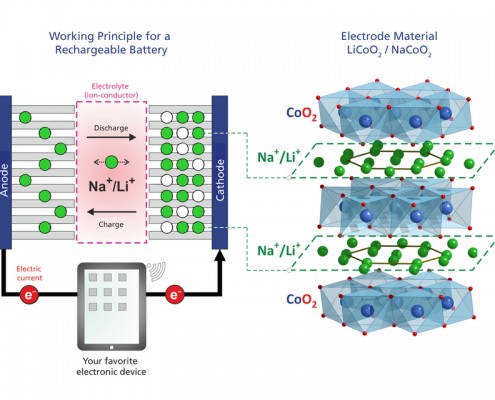

Other researchers at ETH Zurich are working on sodium-ion cells, claiming they will be cheaper than Li-ion, with two major drawbacks: they weigh three times as much and tend to lose capacity when not in use.

Many studies and laboratories, from Imperial College to the German company Bosch, are now turning to the development of Li-S (sulphur), claiming that it will be the 4th generation of batteries, with expectations of up to 400kms of range in the next decade. Scientists at Lawrence Berkeley Laboratory (California) have introduced graphene oxide into Li-S cells with no deterioration over 1500 charge cycles.

Other researchers at ETH Zurich are working on sodium-ion cells, claiming they will be cheaper than Li-ion, with two major drawbacks: they weigh three times as much and tend to lose capacity when not in use.

Li-ion developers such as Bosch, GS Yuasa and Mitsubishi claim that prices can still be halved and capacity doubled, which would bring electric vehicles closer to all consumers.

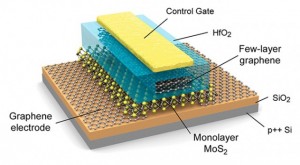

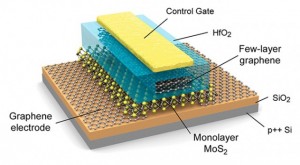

There are also many promising carbon breakthroughs, but the distance between labs and factories is too great to stop producing Li-ion cells for electric vehicles.

Li-ion developers such as Bosch, GS Yuasa and Mitsubishi claim that prices can still be halved and capacity doubled, which would bring electric vehicles closer to all consumers.

There are also many promising carbon breakthroughs, but the distance between labs and factories is too great to stop producing Li-ion cells for electric vehicles.

As published by the magazine "Electric & Hybrid Vehicle Technology International" in its July 2014 issue on carbon:

"The real deal. A new type of carbon-based battery, which could be the game-changer for electric vehicles, has been launched by a Japanese company called Ryden. They claim it has the same electrical density as Li-ion, but with an infinitely longer cycle life, and much safer. Ryden's batteries are made of a more complex chemistry where the anode and cathode are made of carbon.

As published by the magazine "Electric & Hybrid Vehicle Technology International" in its July 2014 issue on carbon:

"The real deal. A new type of carbon-based battery, which could be the game-changer for electric vehicles, has been launched by a Japanese company called Ryden. They claim it has the same electrical density as Li-ion, but with an infinitely longer cycle life, and much safer. Ryden's batteries are made of a more complex chemistry where the anode and cathode are made of carbon.

In terms of performance, not only do these cells hold more than 4 volts, but charging times are 20 times faster than current Li-ion designs. In terms of production, manufacturing processes can be easily modified for future demands, and material supply is also assured as the only active material is carbon. Charging cycles can be higher than 3000 and fire hazards are eliminated as there is very little thermal difference in the state of charge. Finally, Ryden says the batteries can be charged and discharged at 100%, and would also be 100% recyclable. In the future, they plan to replace carbon from mineral sources with natural sources, such as cotton, and want to control the size of the carbon crystals in the production of the carbon.

In terms of performance, not only do these cells hold more than 4 volts, but charging times are 20 times faster than current Li-ion designs. In terms of production, manufacturing processes can be easily modified for future demands, and material supply is also assured as the only active material is carbon. Charging cycles can be higher than 3000 and fire hazards are eliminated as there is very little thermal difference in the state of charge. Finally, Ryden says the batteries can be charged and discharged at 100%, and would also be 100% recyclable. In the future, they plan to replace carbon from mineral sources with natural sources, such as cotton, and want to control the size of the carbon crystals in the production of the carbon.

Fresh air, to come.

Until now, the most obvious battery technology has been lithium-ion. But, for some time now, a new air-based technology has been the main focus of interest for electric vehicle manufacturers and researchers. The new Li-air batteries promise to have 10 times the energy density of their Li-ion cousins. IBM launched Project 500, which aimed to get 500 miles on a single charge using a family car. Using these new batteries. However, this has already been achieved by the Metron Institute (Slovenia) with LiFePo4 technology. The way a li-air cell works is that they use a cheap carbon cathode (rather than cobalt), and an oxygen molecule pivots around the cathode, hence the name. But this is still theoretical because of the major challenges to overcome, such as the anode in these batteries is pure lithium metal, which provides a lot of energy but ignites in the presence of water or other pollutants.

Such was the challenge, that both IBM and JCESR (Centre for Energy Storage Research) have taken a step back from Li-air development, and IBM has now shifted in favour of lithium-sodium technology.

The way a li-air cell works is that they use a cheap carbon cathode (rather than cobalt), and an oxygen molecule pivots around the cathode, hence the name. But this is still theoretical because of the major challenges to overcome, such as the anode in these batteries is pure lithium metal, which provides a lot of energy but ignites in the presence of water or other pollutants.

Such was the challenge, that both IBM and JCESR (Centre for Energy Storage Research) have taken a step back from Li-air development, and IBM has now shifted in favour of lithium-sodium technology.

But with all these changes, new developments continue, and in metal chemistry there are still new developments, in particular in aluminium-air batteries. One Israeli company, Phinergy, claims to have solved corrosion and recharging problems with a silver-based catalyst. They claim to have built a prototype electric vehicle with a range of 1600kms using aluminium-air batteries. However, these batteries cannot be recharged electrically and have to be filled with water.

But with all these changes, new developments continue, and in metal chemistry there are still new developments, in particular in aluminium-air batteries. One Israeli company, Phinergy, claims to have solved corrosion and recharging problems with a silver-based catalyst. They claim to have built a prototype electric vehicle with a range of 1600kms using aluminium-air batteries. However, these batteries cannot be recharged electrically and have to be filled with water.

It smells of sulphur.

Lithium-sulphur cells are another avenue of energy density research that could solve the problems of electric vehicles in the near future. This new technology aims to solve the problems of battery life cycles and stability. Based on carbon electrodes, it is said that they could overtake lithium-air technology. Many studies and laboratories, from Imperial College to the German company Bosch, are now turning to the development of Li-S (sulphur), claiming that it will be the 4th generation of batteries, with expectations of up to 400kms of range in the next decade. Scientists at Lawrence Berkeley Laboratory (California) have introduced graphene oxide into Li-S cells with no deterioration over 1500 charge cycles.

Other researchers at ETH Zurich are working on sodium-ion cells, claiming they will be cheaper than Li-ion, with two major drawbacks: they weigh three times as much and tend to lose capacity when not in use.

Many studies and laboratories, from Imperial College to the German company Bosch, are now turning to the development of Li-S (sulphur), claiming that it will be the 4th generation of batteries, with expectations of up to 400kms of range in the next decade. Scientists at Lawrence Berkeley Laboratory (California) have introduced graphene oxide into Li-S cells with no deterioration over 1500 charge cycles.

Other researchers at ETH Zurich are working on sodium-ion cells, claiming they will be cheaper than Li-ion, with two major drawbacks: they weigh three times as much and tend to lose capacity when not in use.

Lithium-ion are here to stay.

Despite all the developments in the field of energy storage, one thing is clear, most electric vehicles currently use li-ion, and the fact that manufacturers are offering cheaper prices and even Tesla is setting up a lithium battery plant, suggests that in the long term this technology is here to stay. Li-ion developers such as Bosch, GS Yuasa and Mitsubishi claim that prices can still be halved and capacity doubled, which would bring electric vehicles closer to all consumers.

There are also many promising carbon breakthroughs, but the distance between labs and factories is too great to stop producing Li-ion cells for electric vehicles.

Li-ion developers such as Bosch, GS Yuasa and Mitsubishi claim that prices can still be halved and capacity doubled, which would bring electric vehicles closer to all consumers.

There are also many promising carbon breakthroughs, but the distance between labs and factories is too great to stop producing Li-ion cells for electric vehicles.

As published by the magazine "Electric & Hybrid Vehicle Technology International" in its July 2014 issue on carbon:

"The real deal. A new type of carbon-based battery, which could be the game-changer for electric vehicles, has been launched by a Japanese company called Ryden. They claim it has the same electrical density as Li-ion, but with an infinitely longer cycle life, and much safer. Ryden's batteries are made of a more complex chemistry where the anode and cathode are made of carbon.

As published by the magazine "Electric & Hybrid Vehicle Technology International" in its July 2014 issue on carbon:

"The real deal. A new type of carbon-based battery, which could be the game-changer for electric vehicles, has been launched by a Japanese company called Ryden. They claim it has the same electrical density as Li-ion, but with an infinitely longer cycle life, and much safer. Ryden's batteries are made of a more complex chemistry where the anode and cathode are made of carbon.

In terms of performance, not only do these cells hold more than 4 volts, but charging times are 20 times faster than current Li-ion designs. In terms of production, manufacturing processes can be easily modified for future demands, and material supply is also assured as the only active material is carbon. Charging cycles can be higher than 3000 and fire hazards are eliminated as there is very little thermal difference in the state of charge. Finally, Ryden says the batteries can be charged and discharged at 100%, and would also be 100% recyclable. In the future, they plan to replace carbon from mineral sources with natural sources, such as cotton, and want to control the size of the carbon crystals in the production of the carbon.

In terms of performance, not only do these cells hold more than 4 volts, but charging times are 20 times faster than current Li-ion designs. In terms of production, manufacturing processes can be easily modified for future demands, and material supply is also assured as the only active material is carbon. Charging cycles can be higher than 3000 and fire hazards are eliminated as there is very little thermal difference in the state of charge. Finally, Ryden says the batteries can be charged and discharged at 100%, and would also be 100% recyclable. In the future, they plan to replace carbon from mineral sources with natural sources, such as cotton, and want to control the size of the carbon crystals in the production of the carbon.

Great work, all the best

Thank you. Here, with the batteries, there is still a lot of work to be done.

I'd like to find out more? I'd like to find out some additional information.

Hello Eco friendly,

What exactly you need to know. Do you have a project in mind?. Let us know and we or other users may be able to help you.

Reagrds

Excellent!

Lots of encouragement for further research

Years ago I read a book by a Catalan who converted a Renault Gordini to electrification, I thought that was the future.

But today there are many of us who think the same, and it is already present, it has been achieved, there are still legal issues and information to be made available.

Remain true to the ideas that move our world.

Greetings to all the followers of the block.

I love your project!!!!!

Go ahead!!!!

Great news

hello, could someone tell me the price of the batteries?

THANK YOU!

Hello,

As an example, batteries for 100kms for a small vehicle could cost between 4000€ and 5000€, depending on the price of lithium that month.

Best regards