This is one of the most important mechanical manipulations you will have to make when converting your vehicle to electric, if not the most important. Coupling the electric motor to the existing transmission is an ongoing debate, as you can either connect the two axles with some kind of coupling or do it with the clutch.

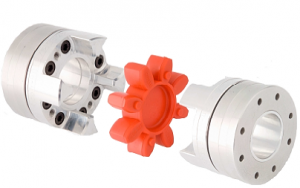

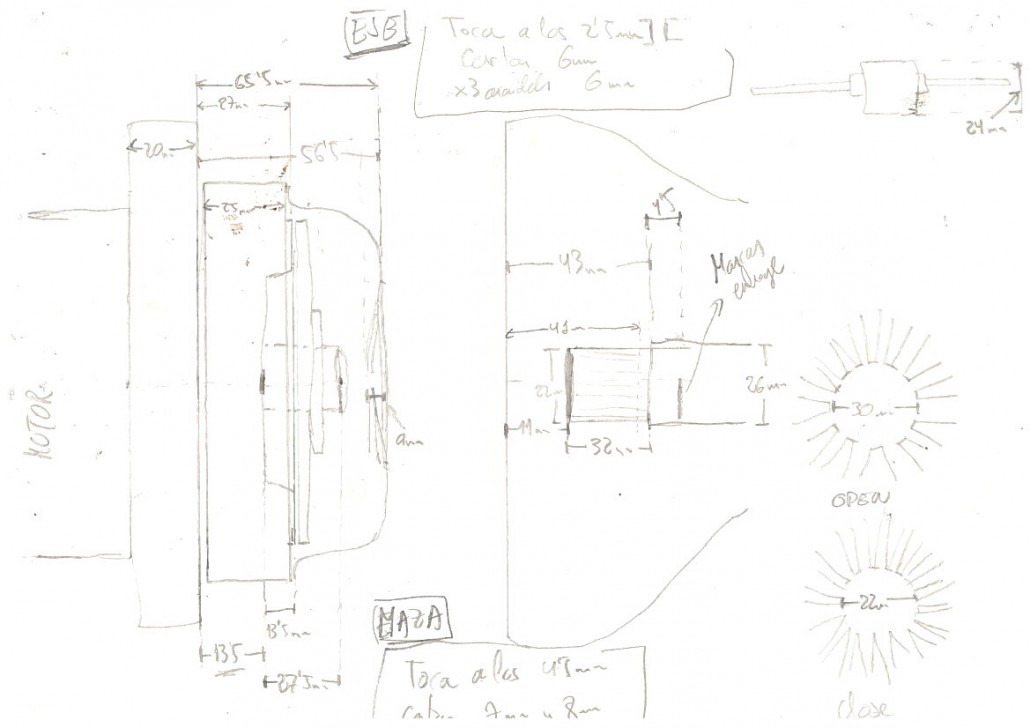

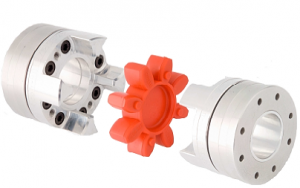

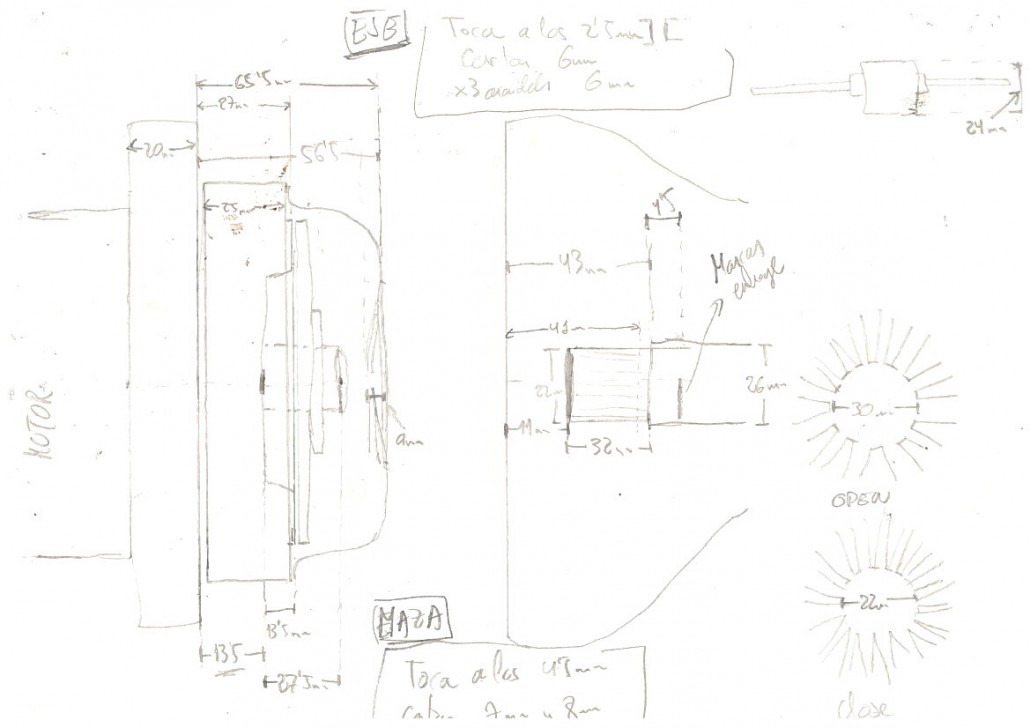

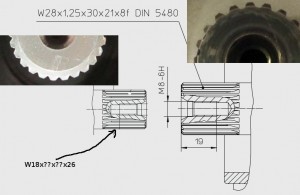

Normally, both shafts have different diameters, different splines or are flat cylindrical with a grind, so you will need two different couplings, one for each bearing (engine and gearbox).

Picture 51

Now, these two couplings can be connected directly or using the original clutch (there is already a big debate about this). In our case, we follow the design with the clutch. The main reason is for efficiency, as having the possibility to change gears will give us more efficiency in all cases like output, low, medium and high gears. Although this approach to the coupling is a bit more complicated to implement, as the inertia disc has to be adapted to the electric motor's shaft, the driving of the car will be similar to the same with the petrol engine.

The first thing in this transformation is to have the adapter plate ready and mounted on the engine, so that the flywheel keeps the same position in relation to the gearbox.

Now, these two couplings can be connected directly or using the original clutch (there is already a big debate about this). In our case, we follow the design with the clutch. The main reason is for efficiency, as having the possibility to change gears will give us more efficiency in all cases like output, low, medium and high gears. Although this approach to the coupling is a bit more complicated to implement, as the inertia disc has to be adapted to the electric motor's shaft, the driving of the car will be similar to the same with the petrol engine.

The first thing in this transformation is to have the adapter plate ready and mounted on the engine, so that the flywheel keeps the same position in relation to the gearbox.

Next, we need to fit the flywheel to the motor with an adapter. You can use a steel coupling from Lovejoy or Rotex, turned exactly for the shaft of the electric motor. It is very important to measure all the components inside the gearbox, including the clutch, so that everything fits perfectly.

Once you have the flywheel modified and mounted on the engine, it is time to assemble the clutch to the flywheel. From this point on, the operation is basic clutch installation.

Next, we need to fit the flywheel to the motor with an adapter. You can use a steel coupling from Lovejoy or Rotex, turned exactly for the shaft of the electric motor. It is very important to measure all the components inside the gearbox, including the clutch, so that everything fits perfectly.

Once you have the flywheel modified and mounted on the engine, it is time to assemble the clutch to the flywheel. From this point on, the operation is basic clutch installation.

On the 1st attempt to install the clutch, everything went well, except that there was a small periodic noise inside the gearbox. So we had to take it apart again to see what had happened. Our surprise was that the flywheel was rubbing inside the gearbox. This was the first problem easily solved by eating a little inside the gearbox in the areas where the flywheel was touching.

On the 1st attempt to install the clutch, everything went well, except that there was a small periodic noise inside the gearbox. So we had to take it apart again to see what had happened. Our surprise was that the flywheel was rubbing inside the gearbox. This was the first problem easily solved by eating a little inside the gearbox in the areas where the flywheel was touching.

The second problem was the flywheel itself, even if it was correctly inserted into the splined bearing of the electric motor, it was not fixed, so the centrifugal force could cause the flywheel to move forward and touch the bearing of the gearbox. Therefore, apart from welding a coupling in the centre of the flywheel, we asked for a hole to be drilled so that the flywheel could be bolted to the bearing.

But this modification caused the clutch flywheel block to move 6 mm forward, so we had to cut 7 mm off the gearbox bearing.

The second problem was the flywheel itself, even if it was correctly inserted into the splined bearing of the electric motor, it was not fixed, so the centrifugal force could cause the flywheel to move forward and touch the bearing of the gearbox. Therefore, apart from welding a coupling in the centre of the flywheel, we asked for a hole to be drilled so that the flywheel could be bolted to the bearing.

But this modification caused the clutch flywheel block to move 6 mm forward, so we had to cut 7 mm off the gearbox bearing.

We also discovered that the flywheel did not rotate perfectly flat with respect to the shaft, so we sent it to the lathe operator to rectify this small difference and reduce the diameter of the flywheel on the way; with this we solved 2 issues. By removing mass we reduce the flywheel inertia and prevent it from rubbing inside the gearbox.

We also discovered that the flywheel did not rotate perfectly flat with respect to the shaft, so we sent it to the lathe operator to rectify this small difference and reduce the diameter of the flywheel on the way; with this we solved 2 issues. By removing mass we reduce the flywheel inertia and prevent it from rubbing inside the gearbox.

The final result. Third time lucky. The flywheel rotates flat with the clutch disc, adjusted to the electric motor bearing, the diameter of the flywheel is much smaller, so that it does not touch anything at all and has less mass, and therefore less inertia and better performance. We also needed to balance it (so that it would not vibrate at high revs), but as it was already balanced from the factory we were confident that it would stay that way after the rectification. The gearbox bearing was shortened by 7 mm to receive the engine block and everything fit like a glove once it was modified.

Photo 57

The final result. Third time lucky. The flywheel rotates flat with the clutch disc, adjusted to the electric motor bearing, the diameter of the flywheel is much smaller, so that it does not touch anything at all and has less mass, and therefore less inertia and better performance. We also needed to balance it (so that it would not vibrate at high revs), but as it was already balanced from the factory we were confident that it would stay that way after the rectification. The gearbox bearing was shortened by 7 mm to receive the engine block and everything fit like a glove once it was modified.

Photo 57

The final result was quite good. It was tested at high revs with no vibration at all.

The final result was quite good. It was tested at high revs with no vibration at all.

Now, these two couplings can be connected directly or using the original clutch (there is already a big debate about this). In our case, we follow the design with the clutch. The main reason is for efficiency, as having the possibility to change gears will give us more efficiency in all cases like output, low, medium and high gears. Although this approach to the coupling is a bit more complicated to implement, as the inertia disc has to be adapted to the electric motor's shaft, the driving of the car will be similar to the same with the petrol engine.

The first thing in this transformation is to have the adapter plate ready and mounted on the engine, so that the flywheel keeps the same position in relation to the gearbox.

Now, these two couplings can be connected directly or using the original clutch (there is already a big debate about this). In our case, we follow the design with the clutch. The main reason is for efficiency, as having the possibility to change gears will give us more efficiency in all cases like output, low, medium and high gears. Although this approach to the coupling is a bit more complicated to implement, as the inertia disc has to be adapted to the electric motor's shaft, the driving of the car will be similar to the same with the petrol engine.

The first thing in this transformation is to have the adapter plate ready and mounted on the engine, so that the flywheel keeps the same position in relation to the gearbox.

Next, we need to fit the flywheel to the motor with an adapter. You can use a steel coupling from Lovejoy or Rotex, turned exactly for the shaft of the electric motor. It is very important to measure all the components inside the gearbox, including the clutch, so that everything fits perfectly.

Once you have the flywheel modified and mounted on the engine, it is time to assemble the clutch to the flywheel. From this point on, the operation is basic clutch installation.

Next, we need to fit the flywheel to the motor with an adapter. You can use a steel coupling from Lovejoy or Rotex, turned exactly for the shaft of the electric motor. It is very important to measure all the components inside the gearbox, including the clutch, so that everything fits perfectly.

Once you have the flywheel modified and mounted on the engine, it is time to assemble the clutch to the flywheel. From this point on, the operation is basic clutch installation.

On the 1st attempt to install the clutch, everything went well, except that there was a small periodic noise inside the gearbox. So we had to take it apart again to see what had happened. Our surprise was that the flywheel was rubbing inside the gearbox. This was the first problem easily solved by eating a little inside the gearbox in the areas where the flywheel was touching.

On the 1st attempt to install the clutch, everything went well, except that there was a small periodic noise inside the gearbox. So we had to take it apart again to see what had happened. Our surprise was that the flywheel was rubbing inside the gearbox. This was the first problem easily solved by eating a little inside the gearbox in the areas where the flywheel was touching.

The second problem was the flywheel itself, even if it was correctly inserted into the splined bearing of the electric motor, it was not fixed, so the centrifugal force could cause the flywheel to move forward and touch the bearing of the gearbox. Therefore, apart from welding a coupling in the centre of the flywheel, we asked for a hole to be drilled so that the flywheel could be bolted to the bearing.

But this modification caused the clutch flywheel block to move 6 mm forward, so we had to cut 7 mm off the gearbox bearing.

The second problem was the flywheel itself, even if it was correctly inserted into the splined bearing of the electric motor, it was not fixed, so the centrifugal force could cause the flywheel to move forward and touch the bearing of the gearbox. Therefore, apart from welding a coupling in the centre of the flywheel, we asked for a hole to be drilled so that the flywheel could be bolted to the bearing.

But this modification caused the clutch flywheel block to move 6 mm forward, so we had to cut 7 mm off the gearbox bearing.

We also discovered that the flywheel did not rotate perfectly flat with respect to the shaft, so we sent it to the lathe operator to rectify this small difference and reduce the diameter of the flywheel on the way; with this we solved 2 issues. By removing mass we reduce the flywheel inertia and prevent it from rubbing inside the gearbox.

We also discovered that the flywheel did not rotate perfectly flat with respect to the shaft, so we sent it to the lathe operator to rectify this small difference and reduce the diameter of the flywheel on the way; with this we solved 2 issues. By removing mass we reduce the flywheel inertia and prevent it from rubbing inside the gearbox.

The final result. Third time lucky. The flywheel rotates flat with the clutch disc, adjusted to the electric motor bearing, the diameter of the flywheel is much smaller, so that it does not touch anything at all and has less mass, and therefore less inertia and better performance. We also needed to balance it (so that it would not vibrate at high revs), but as it was already balanced from the factory we were confident that it would stay that way after the rectification. The gearbox bearing was shortened by 7 mm to receive the engine block and everything fit like a glove once it was modified.

Photo 57

The final result. Third time lucky. The flywheel rotates flat with the clutch disc, adjusted to the electric motor bearing, the diameter of the flywheel is much smaller, so that it does not touch anything at all and has less mass, and therefore less inertia and better performance. We also needed to balance it (so that it would not vibrate at high revs), but as it was already balanced from the factory we were confident that it would stay that way after the rectification. The gearbox bearing was shortened by 7 mm to receive the engine block and everything fit like a glove once it was modified.

Photo 57

The final result was quite good. It was tested at high revs with no vibration at all.

The final result was quite good. It was tested at high revs with no vibration at all.

It seems to me that this is the most complex issue of conversion. Thank you for your valuable comments.

I dont know much about your videos so, i am going ask what might be a dumb question . have you tried a pilot bearing and thrust washers for end play.

We did try, but we weren't convinced.